Literature review about adaptive drilling

May 22, 2021

Table of Contents

Background

To improve product quality and working efficiency, adaptive drilling is proposed.

Definition

Incorporated with process monitoring approaches, adaptive drilling system can automatically make adjustments, such as process parameters(eg. spindle speed, feed rate and coolant settings).1

Example

- Change spindle speed and feed rate depending on cutting material

- Stop coolant spray when drill breaks through the workpieces

- Change tool before incidents such as chip clogging and delaminiation

Key points

The key points of the topic is listed below

- An accurate perception methods

- The relationship between parameters and cutting condition

- Search and optimization methods

Perception methods

The important cutting indexes are listed below

- Cutting material

- Tool’s condition (usually wear level)

- Product quality (eg. surface roughness and burr formation)

Cutting material recognition

In cutting aluminum-composite stacked material, cutting procedure can be divided into 3 parts

- Tool engagement

- Material transition

- Tool disengagement

Drill twist geometry

See link

Tool engagement

Tool begins to engage with workpiece during machining process.

In milling process(slotting)

The angle is important and affects tool forces and temperatures.2

Material transition

In this stage, signals in force, acceleration and acoustic emission(AE) will change gradually.

Force

Main features in material transition stage:

- Force will increase linearly with tool wear

- In the same drilling cycle, force in composite material is lower than in aluminum.

- Oscillation can be found with relatively low frequency.

- Come to 0 when tool break through the workpieces

- Due to increase brought by tool wear, single threshold classification is not applicable.

Acceleration

The acceleration source comes from

- Independent source

- Vibration from foundation

- Part unbalance

- Inertia forces

- Driver inaccuracy

- Dependent source

- Non homogeneity

- Property variation

- Chatter, rotation frequency and mode coupling in tool engagement stage

Main features are listed below:

- Vibration in x-axis is sensitive

- Vibration in CFRP is greater than aluminum

- Peaks gets often as drilled hole increases

- Sudden rise in tool disengagement leads to signal saturated

Acoustic emission

Main features are listed below:

- Drop to 0 means tool’s life ends

- Magnitude rises with tool wear

- Fluctuation indicates severe chip jamming

- There is strong variation

Tool disengagement

Burr will form and final hole quality will be determined in this stage.

Point of angle determines chip formation.

| Point angle | Chisel edge | Chip property |

|---|---|---|

| > 118 | Concave | Improve chip breaking |

| 118 | Straight(Standard) | - |

| < 118 | Convex | Prevent burr* |

*: small point of angle will reduce edge strength and make it prone to chipping and fracturing.

Relation between parameters and cutting condition

Useful papers

- Optimization of varying-parameter drilling for multi-hole parts using metaheuristic algorithm coupled with self-adaptive penalty method3

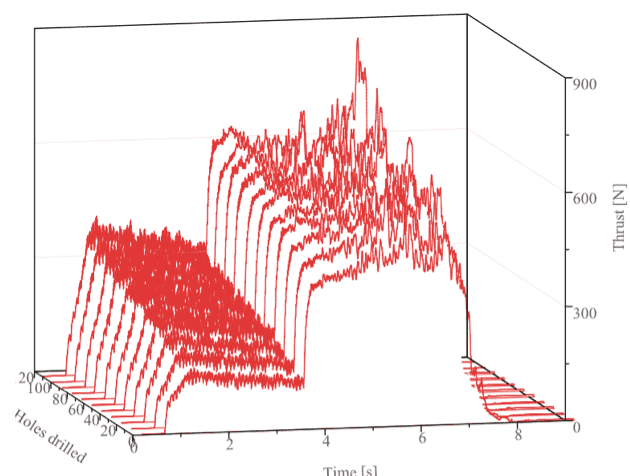

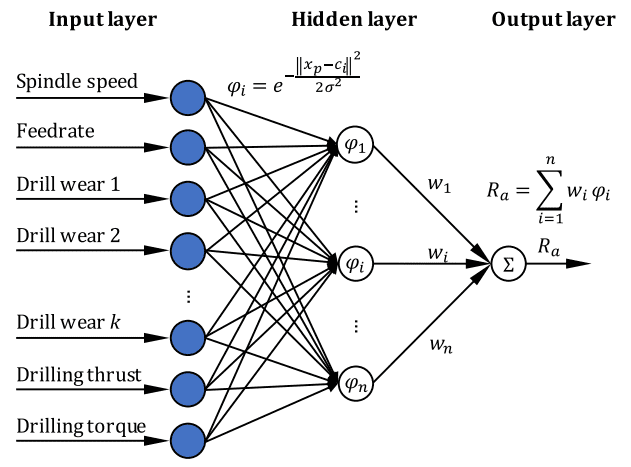

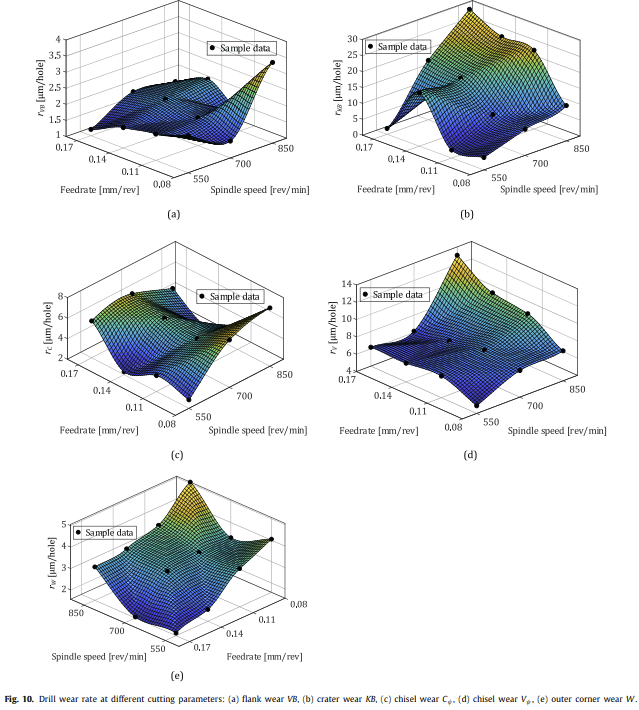

The paper using Radial Basis Function(RBF)-network to model the impact factor from cutting forces, vibration to hole’s surface roughness. Then Gray analysis is used to do reverse engineering. A self-adaptive penalty method based on metaheuristic algorithm is used to find the optimal parameters for drilling process.

The fig below show drill wear at different cutting parameters.

Product quality prediction and optimization

Useful papers

This theme supports link posts, made famous by John Gruber. To use, just add link: http://url-you-want-linked to the post’s YAML front matter and you’re done.1

And this is how a quote looks.

Some link can also be shown.

References

- Pardo, A., Majeed, M., & Heinemann, R. (2020). Process signals characterisation to enable adaptive drilling of aerospace stacks. Procedia CIRP, 88, 479-484.↩

- Adesta, E. Y. T., Hamidon, R., Riza, M., Alrashidi, R. F. F. A., & Alazemi, A. F. F. S. (2018). Investigation of tool engagement and cutting performance in machining a pocket. In IOP Conference Series: Materials Science and Engineering (Vol. 290, No. 1, p. 012066). IOP Publishing.↩

- Han, C., Luo, M., & Zhang, D. (2020). Optimization of varying-parameter drilling for multi-hole parts using metaheuristic algorithm coupled with self-adaptive penalty method. Applied Soft Computing, 95, 106489.↩