Initial experiment plans for PhD entry

July 12, 2021

Table of Contents

Aim

- Recognize different drilling stages

- Find the influence of subsampling frequency and its relations with drilling parameters

- Parametric effects on borehole quality

Experiment methodology

Cutting workpiece

Composition

- CFRP

- Aluminum

Size

50mm * 50mm

Joint

Clamped by bolt and screw

Drilling tool

Twist drills

Collected data

Drilling signal will be collected when tool wear, the thickness of both aluminum layer and CFRP will be measured.

Every time before drilling the next holes, the build-up edge and the residual chips in the drill flutes, if any, were cleared away to eliminate the influence of chips on the drilling forces.

Sampling frequency

10000 Hz according to most researchers

Signal

The following signal will be collected by sensor

| Signal type | Sensor |

|---|---|

| Acceleration | Dynamometer |

| Force | Dynamometer |

| Acoustic emission | AE sensor |

| Spindle power | \ |

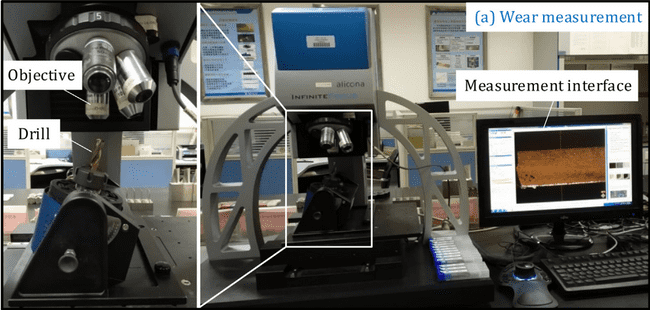

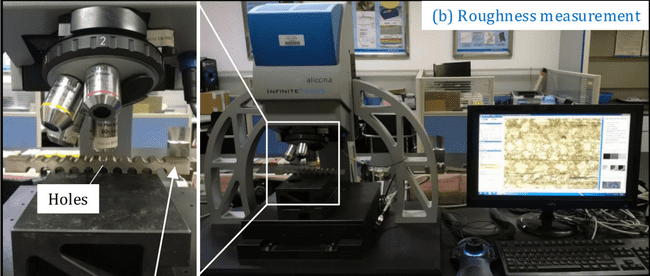

Optical measurements

- Tool wear

- Flank wear

- Crater wear

- Chisel wear

- Outer corner wear

- Cutting Edge rounding

- Thickness of aluminum and CFRP layers

- Borehole surface roughness

For Tool wear

For borehole surface roughness

CFRP dummy plate

To extend tool life

Variant cutting parameters

Drilling setup could follow recommended parameters from tool manufacturer’s manual

- Spindle speed(rev/min)

- Feed rate(mm/rev)